Advanced eDrives for a New Era of Electric Mobility

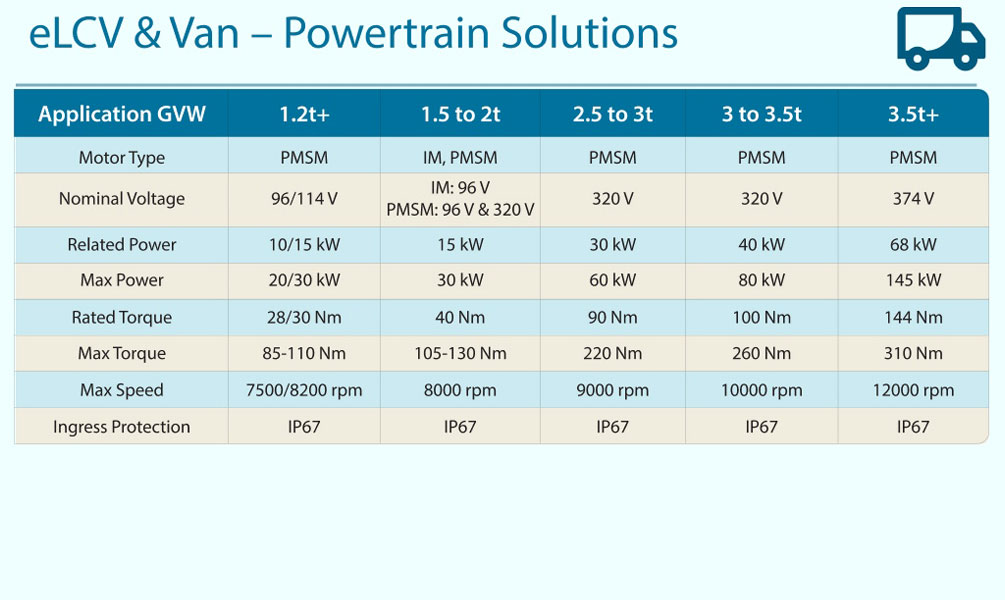

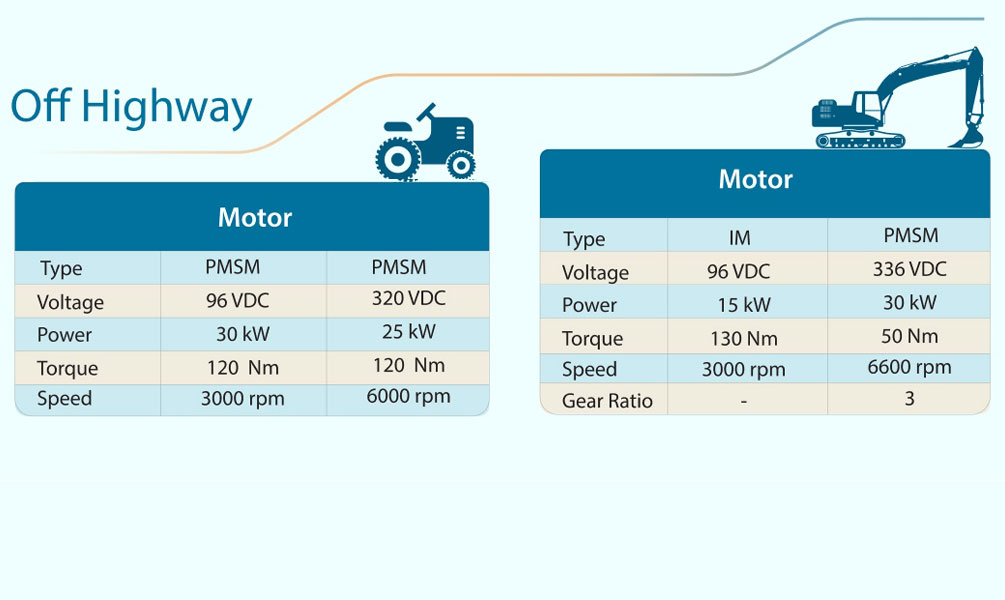

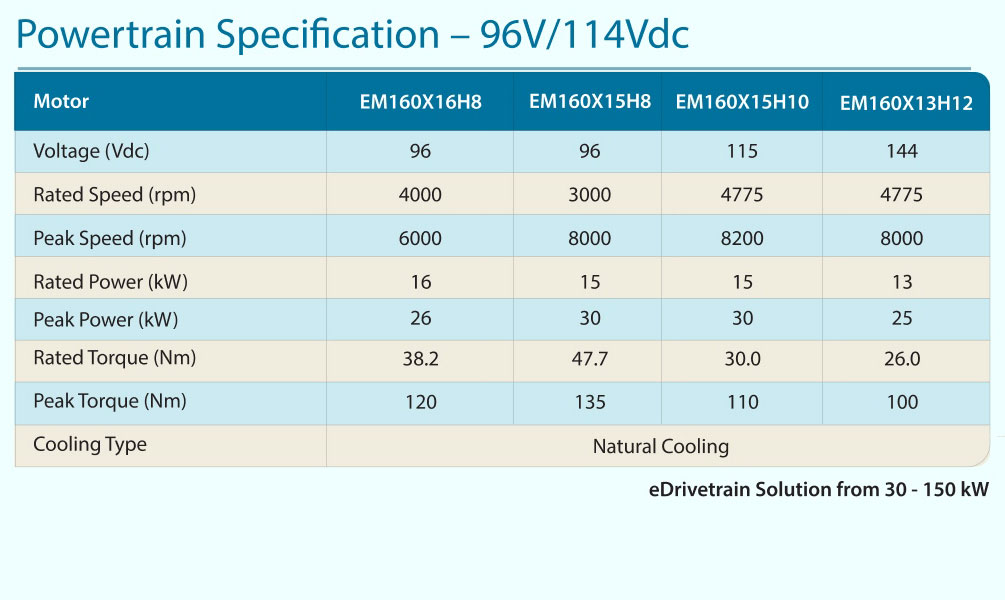

eDrives from Electra EV combine globally proven motor technologies, precision engineering, and intelligent controls for seamless propulsion performance. Each eDrive unit delivers optimal torque, thermal stability, and low NVH across diverse mobility applications ranging from 48V to 750V platforms with power output ranging from 1 kW to 500 kW.

Our eDrives incorporate advanced field-oriented control algorithms for precise torque response and regenerative braking, while adaptive software calibration enhances range and efficiency.

Every system undergoes rigorous validation through performance dynamometers, vibration and thermal endurance testing, and NVH benchmarking, for certification under IATF 16949, ISO 9001, and ISO 14001 frameworks.

Our integrated x-in-1 motor-controller-gearbox architecture eDrives are backed by deep powertrain engineering, enabling OEMs to achieve faster time-to-market, lower integration effort, and superior reliability.

Our eDrive Manufacturing facility underpins this performance with Level-3 interlocked automation, zero-defect assembly processes, and end-to-end digital traceability. Our flexible production lines accommodate both air- and liquid-cooled architectures, enabling rapid configuration for various voltage classes and motor types. Every eDrive unit undergoes rigorous End-of-line (EOL) testing, including dynamometer validation, vibration and noise screening, and fullfunctionality verification under simulated drive cycles.

Electra EV’s eDrive systems stand as a testament to our unwavering pursuit of performance, quality, and customer trust, delivering customer delight from city commutes to rugged terrains. Our eDrives help OEMs achieve global benchmarks in efficiency, refinement, and reliability while advancing cleaner, smarter mobility in an affordable manner.