Powering the Future with Flexible, Digitally Controlled Manufacturing

At the heart of Electra EV’s engineering excellence lies our state-of-the-art manufacturing facility at Coimbatore. The Plant is a precision-driven ecosystem designed to blend automation, digital intelligence, and sustainable practices into every product it creates.

Beyond throughput or localisation, our manufacturing approach embodies a zero-defect manufacturing philosophy, where Level 3 interlocked controls ensure that every task, from fastener torqueing to final assembly, is digitally verified, traceable, and recorded in real-time, reinforcing reliability by inherent design.

Our processes and systems have been benchmarked with the world’s most advanced automotive manufacturing environments. Each workstation functions as an intelligent node within a connected ecosystem. QR coded aggregates initiate operations, and real-time instructions appear on digital screens. Each task requires validation before proceeding to the next stage. Torque-controlled tools, for example, are pre-programmed to multiple load settings and linked to central servers. In this case, the fully digitised tightening and verification system ensures repeatability and precision, and any deviation triggers immediate feedback and corrective action.

Beyond automation, our manufacturing exemplifies adaptive scalability. The Plant’s flexible manufacturing lines are capable of building battery systems ranging from 16 to 250 kWh and powertrain architectures spanning 48 V to 1000+ V, seamlessly reconfigurable for e2W/e3W, passenger vehicles, commercial fleets, off-highway platforms, and stationary storage systems (BESS). Our superior EOL (End-of-Line) testing ensures that performance and safety metrics are achieved under the most demanding real-world conditions for products with the Electra EV stamp of manufacturing.

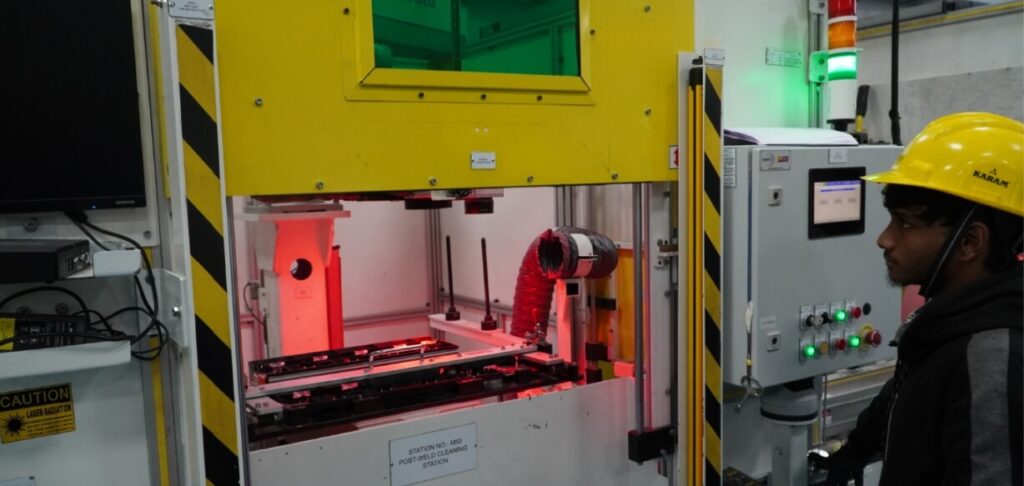

Automation meets intelligence at Electra EV as people and process maturity, high-end infrastructure hardware/software IP, and on-floor efficiency mapping systems come together to compress the development-to-production cycle while maintaining robustness. For example, our Edge-AI–enabled diagnostics and digital twin validation environments for simulation, prognosis, and accelerated development-to-SOP timelines. Again, our rapid OEM customisation capability enables quick adaptation to platform-specific power, packaging, and performance requirements. Our cutting-edge precision laser welding lines ensures high repeatability, structural integrity, and uniform energy performance.

All in all, we have repeatedly created unmatched speed-to-market advantage for OEM partners, enabling custom configurations without compromising on validation, compliance, or final product quality.

While our R&D teams design for diverse operating realities, from extreme temperatures to high-vibration terrains, our manufacturing prowess ensures that every system is engineered not just for lab perfection, but for on-road endurance.

Sustainability is built into our operations through solar-ready rooftops, water recycling systems, and waste minimisation frameworks, ensuring the Plant operates with minimal environmental footprint. Our factory mirrors Electra EV’s broader ESG commitment to responsible manufacturing and circular value creation.

Beyond scale or component-level manufacturing expertise, in today’s competitive landscape, we differentiate ourselves through integration, uniting digital manufacturing, precision quality control, and adaptable engineering into a single ecosystem. Our continuous improvement culture, driven by quality analytics, supplier benchmarking, and the integration of customer feedback, ensures that we remain grounded in ePowertrain realities at all times. At our manufacturing facility, the expertise of our people, world-class machinery, and benchmark processes ensure that every battery pack and edrive from Electra EV carries a promise of safety, reliability, and performance trusted across India’s electric mobility ecosystem.

Manufacturing Highlights

- Level 3 interlocked process controls

- Semi-automatic cell assembly and precision laser welding lines

- Modular, scalable production architecture enabling rapid reconfiguration across multiple platforms

- Integrated real-time monitoring and digital dashboards

- Comprehensive End-of-Line (EOL) testing for 100% verification of electrical, mechanical, and software performance before dispatch.

- In-house validation and reliability testing infrastructure, aligned with ARAI/AIS 004, AIS 037, AIS 038, and AIS 048 standards for crash, vibration, and lifecycle performance.

- IATF 16949:2016, ISO 45001:2018, and ISO 14001:2015, ensuring the highest standards of quality, occupational safety, and environmental management.

- Edge-AI–enabled diagnostics and digital twin validation environments for simulation, prognosis, and accelerated development-to-SOP timelines.

- Multiple inspection and testing gates from cell to pack, including insulation resistance, voltage leakage, and thermal validation.

- Flexible, chemistry and form factor agnostic battery pack production capability

- Sustainability-first operations, featuring solar-ready rooftops, rainwater harvesting, water recycling, and zero-waste manufacturing principles.

- Energy-efficient operations supported by regenerative charging systems and process automation.

- Localised supply chain and FAME-compliant production

- Proven reliability with over 20,000 safe, reliable ePowertrains deployed

- End-to-end digital traceability and compliance